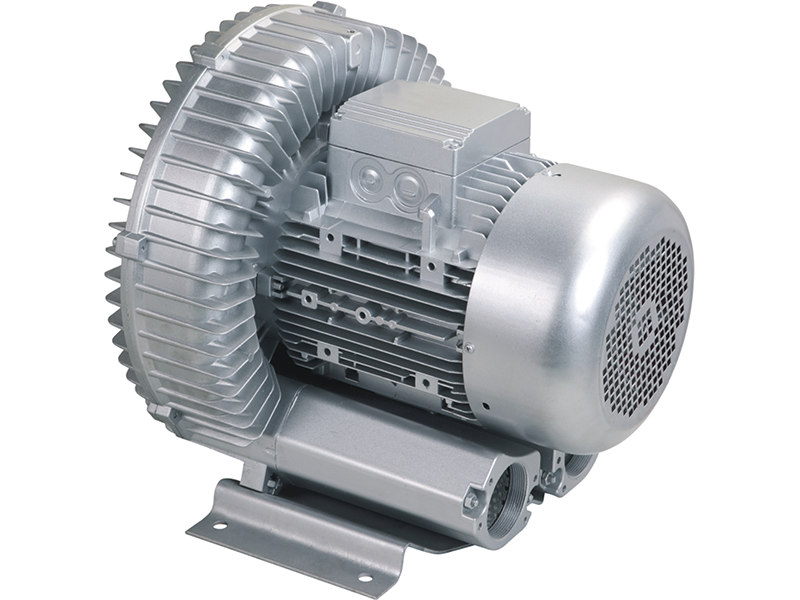

The Three Phase Single Stage Side Channel Blower represents the industrial-grade powerhouse for demanding applications requiring large-volume air delivery and continuous stable compressed air or vacuum sources. Engineered for harsh industrial environments, this blower harnesses the powerful dynamics of three-phase electrical power combined with optimized single-stage design to achieve exceptional volumetric flow rates exceeding 3000 m³/h. This is the standard workhorse configuration for large-scale industrial applications, delivering superior efficiency, reliability, and cost-effectiveness for 24/7 continuous operation.

Factory Building No. 24, Mingyuan Avenue, Fengquanhu High-tech Zone, Chaozhou City, Guangdong Province

© 2026 All Rights Reserved.