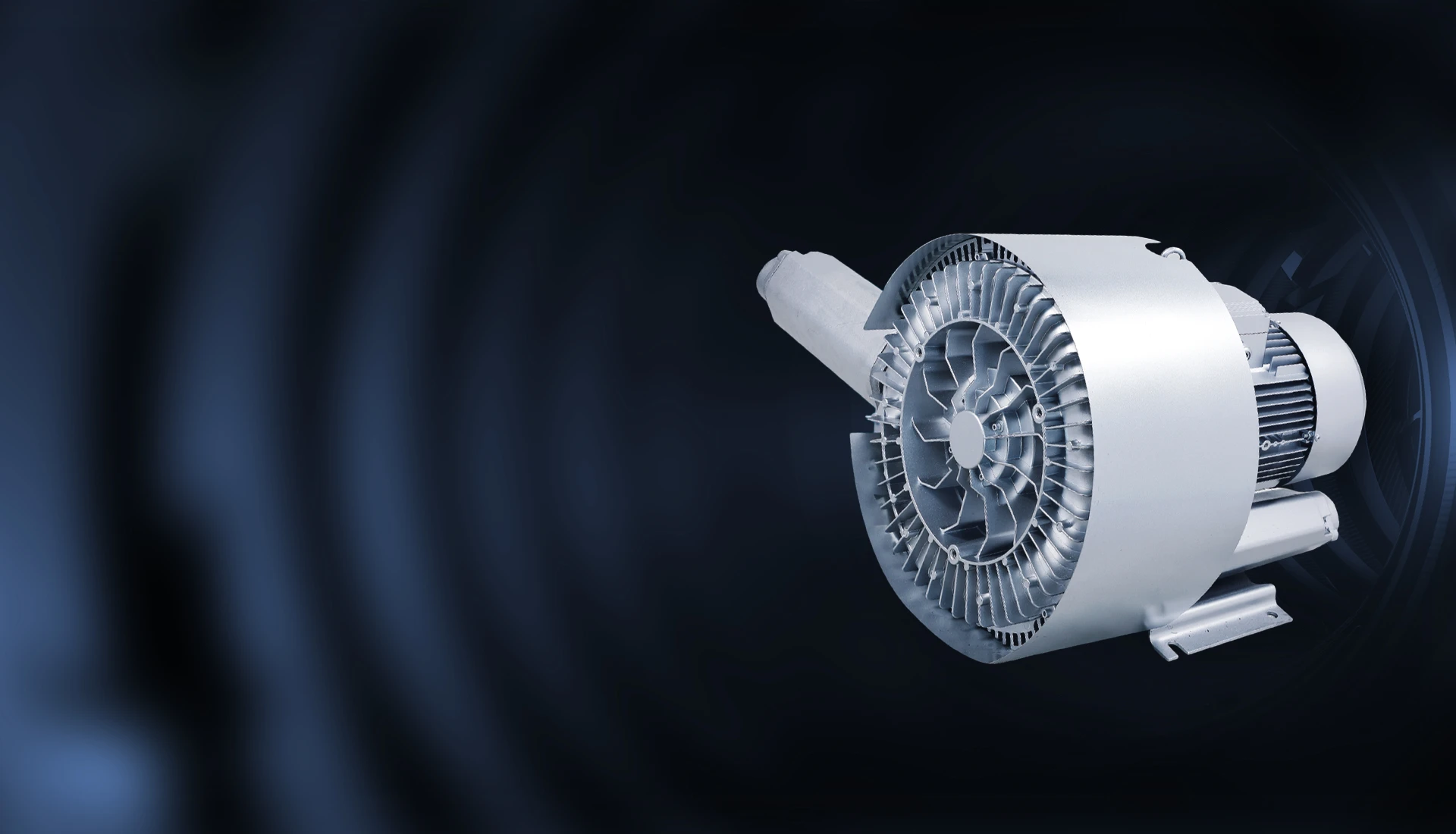

Precision Engineered Vortex Air Pump Solutions for Global Industry

- High-Performance

- Energy-Efficient Side Channel Blowers with Exceptional Durability

- Customization Options

Tailored Solutions for your Unique Challenges

A trusted partner for businesses seeking high-performance fluid handling solutions.

Our Key Value

Voice of Customer

Placing the voice of customers at the center of decision-making, create truly customer-centric products and services by continuously listening, deeply understanding, and actively responding to customer needs.

Partnership Beyond Transactions

We build lasting relationships by understanding each customer’s unique operational context, serving as trusted advisors committed to their long-term success.

Success Measured by Customer Outcomes

We build lasting relationships by understanding each customer’s unique operational context, serving as trusted advisors committed to their long-term success.

No. of years

Square meter

No. of units

Why Choose Our Side Channel Blowers?

Superior Energy Efficiency

1

Advanced aviation aluminum air blades optimize airflow while reducing power consumption.

Innovative Patented Technology

2

Proprietary self-locking muffler structure prevents loosening from vibration while enabling quick disassembly.

Exceptional Durability

3

One-time molded aluminum impellers and thickened cast aluminum shells provide superior corrosion resistance and longevity.

Low Noise Operation

4

Dynamically balanced impellers and precision engineering significantly reduce vibration and noise levels.

Superior Thermal Stability

5

Large heat sink area design ensures optimal cooling during continuous operation.

Maintenance-Free Design

6

Premium materials and sealed bearings minimize maintenance requirements and reduce total ownership costs.

All-Copper Wire Motor

7

Computerized winding with thickened copper wire delivers sufficient power and extended service life.

Versatile Performance

8

Wide operating range maintains consistent performance across various conditions while offering compact integration.

Explore amazing use cases from Side Channel Blower

Precise pressure control systems providing stable power for injection molding, extrusion, and cooling processes with enhanced product quality.

PLASTIC MACHINERY

01

Reliable airflow solutions for efficient and contamination-free transport of powders, granules, and bulk materials.

PNEUMATIC CONVEYING

02

Efficient aeration systems providing continuous oxygen supply to fish and shrimp ponds for optimal aquatic health and enhanced farming productivity.

AQUACULTURE (Fish & Shrimp Pond Aeration)

03

Powerful aeration systems delivering optimal oxygen levels for biological treatment processes and efficient wastewater purification.

WASTEWATER TREATMENT

04

Clean-grade vacuum systems ensuring sterile production environments and strict quality control standards in pharmaceutical manufacturing.

PHARMACEUTICAL MACHINERY

05

GARMENT MACHINERY Precision airflow control systems providing consistent power for sewing, pressing, and finishing processes with superior garment quality.

GARMENT MACHINERY

06

Hygienic vacuum systems providing safe and reliable food-grade solutions for vacuum packaging, material conveying, and drying processes.

FOOD PROCESSING INDUSTRY

07

Powerful dust extraction systems effectively removing wood chips and sawdust for safe working environments and optimal equipment performance.

WOOD PROCESSING MACHINERY

08

Voices across industry leaders

The side channel blowers we integrated into our pneumatic conveying system have revolutionized our powder handling process. Transfer efficiency increased by 32% while reducing product degradation by nearly 50%. The consistent airflow and precise pressure control ensure gentle handling of our most sensitive ingredients, and the oil-free operation maintains our strict contamination standards.

David Martinez

Production Manager, Global Food Ingredients

After integrating these Ring Blowers into our pharmaceutical powder transfer system, we’ve seen remarkable improvements. Cross-contamination risks have been eliminated thanks to the oil-free operation, and the precise pressure control has reduced material waste by 28%. The energy consumption is 35% lower than our previous system while achieving better transfer rates and gentler material handling.

Dr. Lisa Wong

Process Engineering Director, MediPharm Solutions

These regenerative blowers have transformed the material handling component of our injection molding process. The consistent vacuum level has improved our material feed precision by 40%, directly enhancing part quality and reducing reject rates. We’ve also seen a 22% reduction in cycle times and 18% energy savings compared to our previous system.

Richard Taylor

Production Director, AutoParts Precision

Integrating these side channel blowers into our injection molding machines has delivered exceptional results. The precise vacuum control has virtually eliminated surface defects on high-gloss components, reducing our rejection rate by 35%. The system’s reliability has been outstanding—zero unplanned downtime in 14 months of continuous operation across three production lines.

Jennifer Lee

Quality Assurance Manager, TechCase International

Integrating these side channel blowers into our pond aeration system has dramatically improved water quality and fish health. Dissolved oxygen levels have increased by 45% throughout the pond, allowing us to safely increase stocking density by 30%. The corrosion-resistant construction has withstood our harsh saltwater environment without any signs of deterioration.

Sarah Johnson

Operations Director, Atlantic Aquafarms

We integrated these ring blowers into our bottle drying line, and the results have been remarkable. Drying efficiency improved by 35%, allowing us to increase production speed by 20% without compromising quality. The consistent airflow has eliminated the moisture-related rejections that plagued our previous system.

Maria Sanchez

Production Director, EuroFood Systems

Ready to Optimize Your Operations?

Our technical experts are ready to help you find the perfect side channel blower solution for your specific application.