Technical Support

How it works

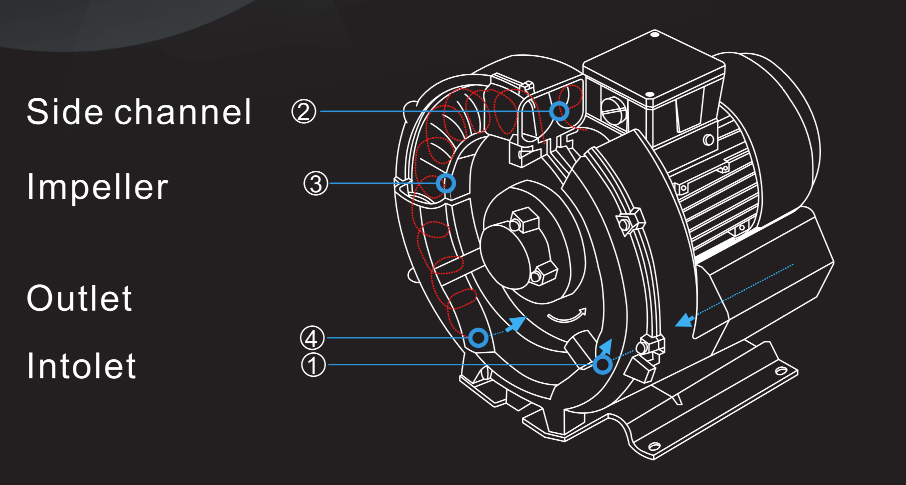

Efficient design creates a continuous flow of pressurized gas without internal contact between moving parts, resulting in exceptional reliability, reduced maintenance requirements, and extended operational lifespan.

Contact-Free Compression Design

The blower impeller is mounted directly on the motor rotor, enabling completely contact-free compression. Since the pump shaft is installed outside the compression chamber, maximum mechanical reliability is ensured even when operating under maximum pressure differentials.

Advanced Gas Flow Dynamics

Gas enters through intake port 1 and flows into the side channel 2. The rotating impeller 3 imparts velocity to the gas in the direction of rotation while simultaneously accelerating it outward through centrifugal force, increasing its pressure.

Progressive Pressure Enhancement

As rotation continues, the gas energy increases, further elevating pressure along the side channel. When the side channel narrows toward the outlet, the gas is forced out from the impeller blades and discharged through outlet silencer 4 completing the compression cycle.

Frequently Asked Questions

Operational Questions

What is the normal operating temperature range for side channel blowers?

Our side channel blowers are designed to operate optimally between 15°C and 40°C ambient temperature. The blower itself may reach temperatures of 70-90°C during normal operation, which is within design parameters. If temperatures exceed 100°C, consult our troubleshooting guide or contact technical support.

How can I reduce the noise level of my side channel blower?

Noise reduction can be achieved through proper installation on vibration isolation mounts, using flexible connectors for inlet and outlet piping, installing the unit in a sound-insulated enclosure (ensuring proper ventilation), and regular maintenance to prevent issues that cause increased noise. Our noise reduction kit is also available for sensitive environments.

What causes pressure fluctuations in my system?

Pressure fluctuations typically result from inconsistent power supply, variable demand in your system, partially clogged filters, developing leaks, or beginning stages of impeller wear. Our pressure monitoring kit can help identify the specific cause in your system.

How often should I expect to replace the impeller?

With proper maintenance and operation within specified parameters, impellers typically last 5-7 years. Factors that can reduce lifespan include abrasive particles in the airstream, operation outside temperature specifications, and frequent cycling on and off.

Maintenance Questions

How often should bearings be replaced?

Under normal operating conditions, bearings should be inspected quarterly and typically require replacement every 15,000-20,000 operating hours (approximately 2-3 years of continuous operation). Signs of bearing wear include increased noise, vibration, and heat generation.

What type of lubricant should be used for bearings?

Our side channel blowers require high-temperature bearing grease with NLGI Grade 2 consistency and temperature rating of at least 150°C. Specific recommended brands and types are listed in your maintenance manual. Never mix different types of grease.

How often should inlet filters be replaced?

Inlet filters should be inspected monthly and replaced when pressure drop across the filter exceeds manufacturer specifications (typically 10-15 mbar). In clean environments, this may be every 3-6 months, while dusty environments may require monthly replacement.

Is it normal for the blower housing to be hot to the touch?

Yes, side channel blower housings typically operate at 70-90°C during normal operation. The housing is designed to dissipate heat from the compression process. However, temperatures exceeding 100°C may indicate insufficient cooling or an operational issue.

Selection and Application Questions

How do I determine the correct blower size for my application?

Proper selection requires calculating your required flow rate (m³/h), pressure (mbar), and considering factors such as altitude, temperature, and duty cycle. Our Selection Guide Tool walks you through the process, or contact our application engineers for personalized assistance.

Can side channel blowers be used with variable frequency drives (VFDs)?

Yes, our side channel blowers are compatible with VFDs, allowing for speed control and energy savings. However, we recommend operating between 30-60 Hz and installing proper harmonic filters to prevent motor damage. Our VFD Integration Guide provides detailed instructions.

Are your blowers suitable for explosive atmospheres?

We offer ATEX-certified models specifically designed for potentially explosive atmospheres. Standard models are not suitable for these environments. Please specify ATEX requirements when ordering and consult our ATEX Compliance Guide for installation requirements.

What is the maximum allowable back pressure for your blowers?

Maximum allowable back pressure varies by model. Operating beyond the specified maximum pressure will cause motor overload, overheating, and premature failure. Each model’s specification sheet lists its maximum pressure rating. Our Selection Guide helps ensure you choose a model with appropriate pressure capabilities.

Installation Questions

Is a concrete foundation required for installation?

While a concrete foundation is ideal for larger units (>5.5 kW), smaller units can be installed on sturdy metal frames or platforms. The mounting surface must be level (within 3mm across the footprint) and capable of supporting 150% of the unit weight to account for dynamic forces.

What clearance is required around the blower for proper cooling?

Maintain minimum clearances of 50cm on all sides and 100cm above the unit to ensure adequate cooling airflow. Additional clearance may be required for maintenance access. Insufficient clearance will result in overheating and reduced service life.

Can the blower be installed outdoors?

Standard models are designed for indoor installation. For outdoor applications, we offer weather-protected models or recommend installing standard units in a weather-proof, well-ventilated enclosure. Consider ambient temperature ranges, protection from precipitation, and UV exposure.

Is it necessary to anchor the blower to the foundation?

Yes, proper anchoring is essential to prevent movement, reduce vibration, and ensure safety. Use anchor bolts sized according to the installation manual, typically 10-16mm diameter depending on the model. In seismic zones, additional anchoring requirements may apply.